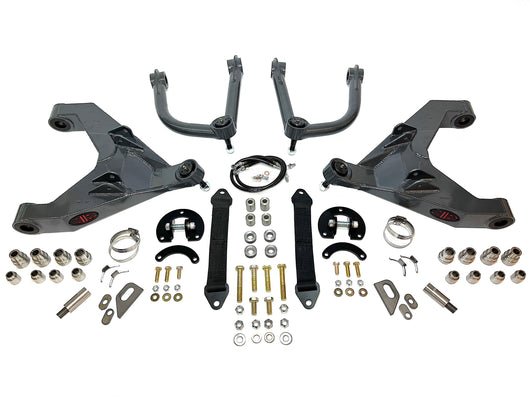

4th Generation 4runner 03-09 6 lug 2.25" long travel kit

- 1 Item

- 4 Items

Regular price

$3,999.95

Sale

-2.25" long travel kit

- YEAR- 2003-2009

- LIFT- 0-3"

- WIDER PER SIDE- 2.25"

- TIRE SIZE RECOMMENDED- 33"-37"

- WHEEL TRAVEL- 13"

- TIRES PUSHED FORWARD- 0.875"

-

PARTS INCLUDED- Upper/lower control arms, all hardware, uniballs, seals, limit straps, brake lines, steering extensions, upper coilover adapter kit for standard 8" King coilovers and all kits come standard with lower bypass shock/limit strap tabs. (axles are NOT included)

- RECOMMENDED SHOCKS- 8"x 2.5" KING coilover and the kit will accept up to a 3.0" 3 tube KING bypass shock. We use custom reservoir hose lengths for the perfect fit.

Now available for the 4th generation 4runner! JD Fabrication has designed and engineered a high clearance long travel kit that provides the best of all worlds for the 4runner. From high speed desert to rock crawling and overlanding this kit does it all while maintaining OE street drive-ability. In the past you were often forced to decide between building a go fast desert rig or a more trail focused rock crawler. The Toyota 4runner armed with this kit gives you the best of both worlds in a package that can be comfortably street driven daily.

The first issue the IFS 4runner has in the rocks is ground clearance, specifically the low hanging control arms. On 4x4 trucks the lower arm has to hang lower than desired in order to clear the front axles and CV's. We took this into consideration when designing our new kit and the solution was to design a "pocket" in the lower arm that the outer CV can sit in thus allowing the arm to gain back the ground clearance typically lost on 4x4 IFS trucks. This design gained almost 4" of ground clearance underneath the control arms!

The second issue with factory 4runner suspension is the available travel range. For off-road applications its ideal to have equal parts up travel as down travel. From the factory the 4runner has more up travel than drop out and this is only made worse once the truck is lifted. For example your typical 4runner with 2-3" lift only has about 2-3" of dropout which makes for a harsh ride off-road. To fix this problem we have changed the travel range to increased dropout and bottom out sooner. This solution has another huge benefit when adding larger sized tires. Anything larger than a 32" tire will smash into the factory core support at full bump. The standard bandaid to this problem is a bump stop spacer but the trade off is decreased wheel travel. When going to a 35" tire this problem becomes much worse and over time the core support will eventually start breaking apart as a result of the tire smashing into it. Our kit slightly limits the up travel to prevent this from happening while increasing the dropout so you still have a full 13" of useable wheel travel. While the factory CV's can handle the increased dropout we strongly recommend up grading to our 934 CV kit for a bullet proof front end.

The third issue with the factory suspension are the rubber bushings Toyota uses for the lower control arms. 4runners are notorious for destroying the lower control arm bushings and the reason is simple- the truck is aligned via the lower control arm. Because the alignment is done with the lower control arms often times the bushings are forced into unnatural positions that create side loads. The combination of the side loading and suspension travel is very hard on the bushings. Larger tires and off-road use really magnify the problem and the result is premature bushing wear which necessitates constant alignments. With our kit we use 1" uniballs which allow for side loading without issue. We machine custom barrels that accept the uniballs without the need for the standard cup. The really neat part about the barrels is the fact that they are designed to accept custom seals so you no longer have to worry about having uniballs exposed to the elements.

The OEM style outer ball joints are great for the factory applications however the stress of larger tires, heavy vehicles and off-road abuse can lead to catastrophic failure. Traditionally 1" uniballs have been used in place of factory style ball joints but we decided to take it one step further! While 1" uniballs are known for their strength they are notorious for premature wear due to the elements. After countless hours of R&D we have come up with what we believe to be the perfect combination of strength and longevity- introducing the "JD Joint!" We start with the highest quality 1" FK uniball available, the WSSX16T. From there we machine our own proprietary 4130 uniball cups and that's where the magic happens. Our cups are machined to accept a 4340 top cap that slides in before the uniball is pressed into the cup. Not only does the top cap seal the uniball from the elements it also provides a bearing surface for the ball to ride on. The additional bearing surface dramatically increases the strength and life of the uniball by distributing the load of the ball on the increased surface area. We also included a zerk fitting on the top cap so a teflon based lubricant can be applied to the underside of the top cap. Due to the design of the sealed top cap a standard bolt can not be used to attach the a-arm to the spindle. Our solution incorporates custom grade 9, 12 point bolts with machined wrench flats on the bolt shank which can be torqued without needing to access the top of the bolt. We also use custom machined misalignment spacers with the factory spindle taper so your a-arms bolt right to the spindle with ZERO drilling or modifications.

In addition to all the problems this kit solves the strength of the kit is unparalleled. All kits are constructed of a combination 1/8" and 3/16" cromoly plate that is laser cut and bent for perfect fitment. The lower arms are built with a complex internal rib structure that is 100% welded inside and out. We also tapered the front face of the lower arm to help them slide over rocks if need be. Secondary bypass shock tabs, bumpstop pads and limit strap tabs are all standard too. Off the shelf 8" King coilovers are used in the kit and we include custom fabricated coilover top hats that bolt into the factory mount. All hardware, extended brake lines, steering extensions and limit straps are also included in the kit. All kits come powder coated and ready to bolt on.

The upper arms use sealed uniball inner pivots, 1.5" DOM tubing construction and custom 4Runner 1" taper EMF outer uniballs.

We recognize that long travel kits are no longer just for the go fast desert guys and we were very specific with selecting the 2.25" length to extend the arms. For guys that are hitting tight, hardcore trails we recommend using a wheel with an offset close to stock as fiberglass will not be required. If you are more geared towards the wide open desert then a negative offset wheel can be run with fiberglass for a very aggressive look. This is also a very daily driver friendly kit with minimal maintenance required thanks in part to the sealed uniball systems. The lower arm also pushes the spindle forward 7/8" which aids in tire clearance as well as increases caster.

If you are after the ultimate 4runner IFS front end we recommend adding our lower control arm pivot kit, 934 CV kit, bypass shock mounts, upper arm double shear kit, spindle gussets and complete steering solution.

Minor drilling and grinding is required for install.

Please note when using our lower pivot kit the lower arm rear misalignment spacers accept a 5/8" bolt. If you are not using the lower pivot kit select the standard LT kit which uses the factory 9/16" cam hardware.